Kalmar One now available as standalone software solution

Kalmar One is an open, vendor-agnostic automation system for all automated terminal operations. Seamlessly interfacing between the TOS, automated equipment and other systems, Kalmar One is a flexible platform for the integration, control and optimization of container movements in automated operations.

“Kalmar One ensures things happen in the right sequence and at the right time, minimising empty driving distances, and enabling terminal operators to do more with a smaller automated fleet,” says Timo Alho, Director Product Management Automation, Kalmar. “This drives greater operational efficiencies while lowering costs, offering a proven, scalable and flexible system to optimise the entire terminal operation.”

One solution, any machine

Kalmar One has been available for several years as part of Kalmar’s terminal automation deliveries, but the solution is now offered, for the first time, as a standalone software product. As a solution, Kalmar One is unique in being able to control all of the automated equipment in a terminal, irrespective of the type and manufacturer of the hardware.

“Along with the standalone availability, the most important thing that we're announcing is that Kalmar One is now fully equipment-agnostic," says Timo Alho. “The system can operate with automated equipment from any vendor, in addition to Kalmar products. To put it simply, you can automate any machine at any terminal, and Kalmar One can be the solution to manage it."

"The ability to procure automated equipment separately from an equipment-agnostic software and automation system also supports our drive towards Automation as a Service offerings in the future," adds Tomi Tuulkari, Director Product Management Automation, Kalmar. “Our customers have been asking for a different business model that would better align the goals of the automation vendor and terminal operator, and we see Automation as a Service as the next step in helping terminals realise the full value of their automated operations."

Kalmar’s recently introduced Automation as a Service model is a subscription-based offering designed for successful and efficient deployment of automation in marine container terminals and intermodal sites. The service model allows for collaborative design and integration testing of automation systems well before the go-live date so that potential gaps in terms of functionality or operational requirements can be identified, ensuring a high-performing automated terminal from day one.

To put it simply, you can automate any machine at any terminal, and Kalmar One can be the solution to manage it.

Optimise the whole, not the parts

A key factor in successfully deploying a terminal automation solution is optimising the automation system for the operations of the entire terminal. "In other words, you don’t want to have a solution in which the cranes are controlled by the crane automation system, the straddle carriers are run by the straddle carrier vendor's software, and so on," says Timo Alho. "Without a single integrated system, it won't be possible to optimise all components for the actual performance targets of the terminal."

Kalmar One is the ideal solution for terminal operators looking to expand and develop their existing terminal operations, as it enables any brand of equipment to be automated. An added opportunity is that the solution allows large terminal operators to standardise their automation across multiple terminals, irrespective of the operation model of each site.

“A single, standardised automation platform not only makes it easier to deploy automation at individual sites, but also to manage internal technical support and other similar functions across the entire company,” says Alho. "Moreover, a common integrated platform facilitates learning from each automation project and reusing successful solutions in the next project, instead of re-inventing the wheel for each case."

In other words, you don’t want to have a solution in which the cranes are controlled by the crane automation system, the straddle carriers are run by the straddle carrier vendor's software, and so on

Proven at megaterminals

In the latest release of Kalmar One, scalability has been developed significantly, and the solution is already used to control automated fleets reliably and efficiently at some of the largest automated terminals in the world.

"We have invested a lot in ensuring that Kalmar One can scale to the operational volumes required by megaterminal operations," says Timo Alho. "As an example, our customer APM Terminals Pier 400 in Los Angeles has been using Kalmar One to manage a fleet of nearly 140 Kalmar AutoStrads™ including functionalities such as scheduling, dispatching and routing."

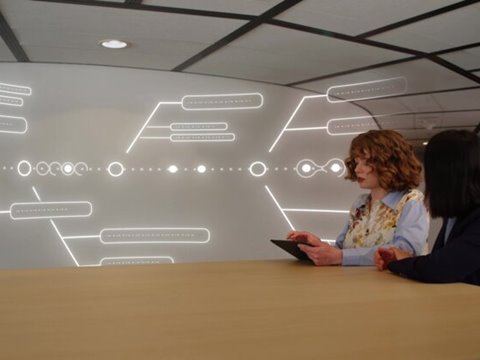

The user interface of the Kalmar One software has also received an update, along with the introduction of more advanced, user-friendly analytics. "The goal has been to give the user a high-level understanding of how the terminal is operating, instead of having to oversee individual container moves," says Tomi Tuulkari. Ultimately, the goal is to provide actionable insights that enable the continuous improvement of efficiency and productivity across the entire terminal.”

To support the growing demand for terminal electrification, Kalmar One now also includes a full suite of functionalities to manage the charging of battery-powered equipment of any type or brand. The scheduling and dispatching functions of Kalmar One can choose the best time for charging the batteries, optimize the usage of charging stations and ensure that there is always an adequate number of machines available for operation.

Emulating for success

In addition to managing live on-site automation, Kalmar One can be used in a digital twin environment for detailed, highly accurate emulation of terminal operations. This enables terminal operators to pre-plan and configure their terminal and equipment fleets, and to run comprehensive tests of the solution with the actual automation system software well in advance of hardware deployment.

“Based on our extensive experience of terminal automation projects, a common challenge is that hardware and software often proceed with very different development schedules,” says Tomi Tuulkari. “Instead of specifying the hardware fleet and then ordering a software solution to automate it, one would ideally plan the entire terminal operation with automation in mind, and then define the layout and hardware accordingly. Emulation and testing with digital twins is crucial for this process, and Kalmar One has been designed to provide terminal operators with an integrated platform that supports them from the first planning steps all the way to ongoing everyday operations.”

In the latest terminal automation cases that Kalmar has been working on, a digital twin environment has been built already in the terminal design phase. This digital twin has been used to carry out emulation test scenarios with different configurations to ensure the right type of equipment is chosen, and the layout is designed in such a way that the automation solution can fulfil the objectives of the terminal operator.

“The only way to understand how the automation software will perform in the complex operational scenarios is to run those scenarios with the real software and validate the outcomes,” says Timo Alho. “Simplified terminal simulation software will never give the same quality of output as a real digital twin. That’s why we recommend utilizing these tools already in the planning phase before the terminal design has been finalized.”

The only way to understand how the automation software will perform in the complex operational scenarios is to run those scenarios with the real software and validate the outcomes

Related articles

Further reading

Subscribe and receive updates in your email

Subscribe